We get asked about beam clamps quite

regularly, so we thought it would be helpful to put together a proper guide

covering the basics and what you need to know.

A beam clamp's job is straightforward - it

grips securely onto steel beams to create a lifting point for hoists and other

equipment. The clamp attaches to the flanges of RSJ, H-beam, or I-beam

structures without requiring any permanent modifications.

Most of our customers choose beam clamps

because they want to avoid drilling holes in their structural steelwork. Once

you drill into a beam, you've potentially weakened it. Beam clamps simply clamp

on, do their job, and can be removed when you're finished.

We've been working with lifting equipment

for over 30 years now, and beam clamps remain one of our most versatile

products in their application.

Construction sites are where we see most of

our beam clamps in use. Contractors use them for positioning air conditioning

units, moving structural steel, and general material handling tasks.

One of our regular customers runs a

manufacturing workshop in Birmingham. When his overhead crane broke down, we

supplied him with a portable gantry system and beam clamps as a temporary

solution. That was three years ago - he's never bothered fixing the original

crane and keeps ordering more clamps for different areas of his workshop.

We also supply quite a few schools and

colleges who use them for stage lighting installations. It makes sense really -

you can't have the drama department drilling holes in the assembly hall

ceiling.

The theatre and events industry is a bit

outside our usual area of expertise, though we do supply some major venues in

London. Different requirements to our typical construction customers, but the

basic principle remains the same.

Getting the beam measurements right is

crucial. You need to know both the flange thickness and width before ordering.

Guessing these dimensions is asking for trouble - either the clamp won't fit

properly, or worse, it might not grip securely.

We've had customers send photos of clamps

that aren't seated correctly because they estimated the beam size rather than

measuring it. Always measure twice, order once.

Safe working loads need careful

consideration too. Don't just match the clamp capacity to your load weight -

allow some safety margin. For straightforward lifts, I'd suggest at least

25-30% above your actual load. For more complex operations or if you're unsure

about any aspect of the lift, go for a higher capacity clamp.

Better to over-spec and be safe than cut

things fine.

LOLER compliance is mandatory - all our

beam clamps come with the necessary certification and documentation, but

regular inspections are your responsibility.

Before each use, check the clamp for any

damage. Look for thread wear, cracks in the body, or anything that prevents

smooth operation. If there's any doubt about the condition, don't use it.

The condition of the beam itself matters

too. Paint, rust, or oil contamination can affect the clamp's grip. Clean the

beam flanges properly before installation - a wire brush takes seconds and

could prevent a serious accident.

Proper tightening is important but don't

overdo it. There's a balance between adequate grip and damaging either the

clamp or the beam structure.

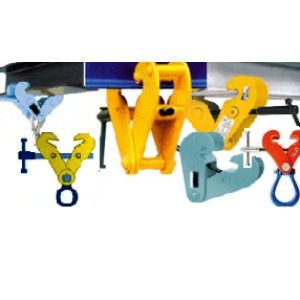

We primarily stock screw-type beam clamps.

They're reliable, fully adjustable, and suitable for most applications. They

take a little longer to position than some alternatives but offer excellent

security once properly installed.

For heavy-duty applications, we have

reinforced models designed for larger loads. These cost more but are engineered

for demanding industrial use.

Our technical team can provide more

specific guidance on specialised requirements.

The biggest error we see is people not

considering the beam's load capacity. Your clamp might be rated for several

tonnes, but if the beam structure can't handle that load, you have a problem.

For significant lifts, always consult with a structural engineer.

Rushing the installation process is another

issue. We understand there's always pressure to get the job done quickly but

taking a few extra minutes to position everything correctly will save time and

prevent problems later.

Using damaged equipment is unfortunately

more common than it should be. If a clamp shows any signs of damage or

excessive wear, replace it. The cost of a new clamp is insignificant compared

to the potential consequences of equipment failure.

Before beam clamps became widely available,

creating temporary lifting points was complicated and time-consuming. You'd

need to weld brackets, drill mounting holes, or make other permanent

modifications to the structure.

Now you can install a secure lifting point

in minutes, move it as needed, and remove it completely when the job's

finished. No structural alterations, no permanent changes - just clean,

efficient lifting solutions.

Beam clamps are straightforward tools that

solve a common problem effectively. Choose the correct size for your beam,

observe proper safety procedures, and they'll provide years of reliable

service.

If you're unsure about specifications or

have specific requirements, please get in touch. Our team can certainly help

you select the right equipment for your needs.

For technical advice or product

enquiries, call us on 01384 76961 or use our website contact form. We're always

happy to help customers find the right lifting solutions.