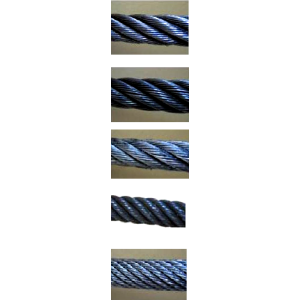

We are often asked about the difference

between stainless steel wire rope and galvanised steel wire rope, and which one

is best for a particular application. It’s a reasonable question, as both

products appear very similar at first glance and, indeed, are designed for the

same general purpose. That being said, getting the wrong wire rope for a

particular task can prove to be a costly error.

Galvanised wire rope, quite simply, is

steel wire rope that’s been galvanised, which basically means that it’s been

coated in a layer of zinc. This provides a reasonable level of protection

against corrosion in most conditions. It’s been the standard wire rope for

general lifting and rigging work for many decades, and it’s hard to argue with

that, as it works well and doesn’t break the bank.

Stainless steel wire rope, by contrast, is

made from a steel alloy that’s been mixed with chromium, and often nickel,

which then provides a protective oxide coating that’s extremely resistant to

corrosion. This isn’t a coating that wears off; it’s a permanent feature of the

wire rope itself.

We stock both types in our warehouse, and

in the 25 years that we’ve been in business, we’ve seen people make bad

decisions with regard to wire rope in both directions – overspending on

stainless steel wire rope when galvanised steel wire rope would have been

perfectly acceptable, and vice versa, trying to cut costs with galvanised steel

wire rope in an application where it simply won’t last.

For most standard lifting and rigging

applications in a relatively dry environment, galvanised wire rope is perfectly

acceptable, and we sell tonnes of it to construction sites, factories, and

workshops throughout the UK.

A customer of ours is a machinery moving

business based in the Midlands. They use galvanised wire rope to load equipment

onto lorries, place machinery in factories, and generally do rigging work. They

get many years of life out of it because the wire rope is not subject to wet

conditions most of the time.

Indoor applications are where galvanised

wire rope is best used. If you are going to be using your wire rope inside, and

it is only going to be subject to wet conditions every now and then, then

galvanised is the way to go. You can save a lot of money versus stainless

steel, especially when dealing with larger diameter wire rope or longer

lengths.

The coating will wear off eventually, and

this is actually a good thing because you can tell when the wire rope is

getting close to the end of its lifespan because the steel underneath the

coating will start to show through.

The first time you should think of using

stainless steel wire rope is when you are going to be near the sea, and the

salt water is going to be subject to the wire rope. The zinc coating will wear

off quickly, and the steel underneath will start to rust and corrode. We sell a

lot of stainless-steel wire rope to marine environments, such as to boat owners

and marinas.

We have a customer who has a fleet of

fishing boats based out of Hull. They tried using galvanised wire rope at first

to save money, but they found that they had to change it every season because

it corroded so quickly. They switched to 316 grade stainless steel, and the

wire rope lasts them years, even in the salty water conditions.

Food processing plants require a wire rope

made from stainless steel due to hygiene reasons. It must be able to withstand

regular washing with cleaning agents and hot water. Galvanised just will not

work; the zinc coating will degrade very quickly.

Chemical plants are yet another example of

where stainless steel can be used. We have sold wire rope to pharmaceutical

companies, water treatment plants, and other industrial sites where the wire

rope is exposed to corrosive substances. Galvanised would not last a month in

some of these places.

Locations near the coast are borderline

cases. Unless your wire rope is going to be regularly dunked in the sea, salt

spray can be quite corrosive. We recommend stainless steel for any permanent

installation within a few miles of the coast.

In terms of specification, when buying

stainless steel wire rope, there are two types: 304 and 316. For most locations

within the UK, we recommend 316, although this is more expensive than 304.

316, or marine grade, wire rope contains

molybdenum, which provides superior corrosion resistance to chlorides. If you

are near the sea or are exposed to road salt in winter, this is an advantage.

We have both types in stock, with 316 making up 80% of our sales of

stainless-steel wire rope. Whilst the difference in cost between 304 and 316 is

not huge, the superior corrosion resistance of 316 is an advantage for many

locations within the UK.

In these types of application, stainless

steel wire rope can be said to have an advantage over both galvanised and

stainless-steel wire ropes, simply by looking at their appearance.

We supplied a hotel refurbishment project

in Manchester with stainless steel rope last year. The architect requested it

for cable railings in the atrium area. While galvanised would have been strong

enough for the structure, it would have looked awful within a year or two as

the zinc coating wears off.

There is no getting around it - stainless

steel wire rope is a lot more expensive than galvanised. You may find yourself

paying two or even three times as much for the same product.

You should also consider the cost of

maintenance and replacement over time, though. If the galvanised rope lasts two

years, and the stainless-steel rope lasts ten years, then it is a lot more

cost-effective in the end.

If it is a one-off or a temporary

application, then galvanised is probably more cost-effective.

Stainless steel wire rope is also slightly

stronger than its galvanised equivalent.

While this may not seem a lot - perhaps

only 10 or 15 percent - it can still be important for applications right on the

limit of the rope's capacity.

A more important consideration is how the

two ropes will hold up over time.

Galvanised rope will lose its strength as

corrosion sets in. The amount of corrosion can vary greatly.

The stainless-steel rope will hold its

rated capacity much more reliably.

Both will handle normal UK temperatures

without any problem.

If you are considering an application for a

cold environment - such as a cold storage warehouse - then the stainless-steel

rope is a better bet as it will remain more flexible at lower temperatures.

While high temperature work is not very

common in what we do, stainless steel performs better under heat than

galvanised rope. Zinc in galvanised rope is not suitable for high temperature

work.

First, consider your environment. If you're

working inside, in a dry environment, not in contact with corrosive substances,

then galvanised rope is perfect for you. Why spend more money than you need to?

Marine environment, coastal regions, food

processing, chemical exposure – all of these factors point towards stainless

steel rope.

How permanent is your installation? Is this

a temporary rigging situation, or is this going to be permanent? If it's

permanent, it would be quite expensive to replace, wouldn't it?

If you're still not sure, play it safe – go

for stainless steel rope. We've never had a customer complain that their

stainless-steel rope was lasting too long or working too well.

Construction (General): Galvanised wire

rope is fine for general construction work.

Marine/Coastal: 316 grade stainless steel

is the only choice for this environment.

Food Processing: Stainless steel is the way

to go for this industry, for obvious reasons.

Manufacturing (indoor): Galvanised is good

for most uses. Consider stainless steel for permanent overhead installation.

Agriculture: It depends on the application,

but galvanised is usually good enough. Consider stainless steel for equipment

washed down frequently.

Architectural: Use stainless steel for

aesthetic reasons as well as performance.

The biggest mistake we've seen people make

is underestimating the corrosiveness of their environment. That "slightly

damp" workshop might be suffering from condensation problems. Those

"occasional" washdowns might be happening too frequently.

Using 304-grade stainless steel in a marine

environment is another mistake. It might be cheaper than 316-grade, but it's

not good enough. Don't make life difficult for yourself - just get the good

stuff.

Don't mix galvanised and stainless steel in

the same installation. It can cause problems with galvanic corrosion. And if

you're using stainless steel wire rope, don't forget to get matching shackles,

thimbles, etc.

Both types of wire ropes need regular

inspection. However, you need to look for different signs of wear.

For the galvanised wire rope, look for

areas where the coating has been stripped away. When you can see the steel

underneath, the wire rope's working life is drawing to a close. Don't worry too

much about the rust - it's a sign the coating has failed.

For the stainless-steel wire rope, it

should look good for a long time. However, don't assume it's invincible. Look

for broken wires, kinks, etc. It might not rust, but it can still break.

Galvanised wire rope is best for use in

indoor applications, for temporary use, or in dry conditions where corrosion is

not a factor. It is also cost-effective and works well in the right conditions.

Stainless steel wire rope is best for use

in marine conditions, coastal areas, food production, chemical environments,

permanent outdoor applications, or for use in areas where appearance is

important. Although more expensive, the wire rope lasts much longer and stands

up much better to corrosion.

If you're unsure of the best wire rope for

your application, our technical staff would be happy to discuss your needs with

you. We've been supplying wire rope to UK businesses for over 25 years, and

we're always happy to use this experience to ensure that our customers get the

best wire rope for the job.

For technical information regarding wire

rope or to discuss your specific needs, contact us on 01384 76961. We offer

both galvanised wire rope and stainless-steel wire rope in various

configurations and diameters.