Available in rope diameters from 1mm up to 26mm in any length. The 1 x 19 stainless steel wire rope in AISI 316 stainless is fairly rigid and has minimal stretch properties. Complies to EN12385 & EN10264.

1x19 stainless steel wire rope is a popular choice for applications requiring strength, minimal stretch, and excellent corrosion resistance. The "1x19" designation refers to its construction which consists of 10 individual wire strands wound tightly together. The resulting rope is relatively stiff compared to the more flexible multi-strand options.

This stainless rope has very low stretch under load, which is crucial for some applications such as static applications and as marine rigging as mast stays.

The 1 x 19 wire rope cis available in a wide range of diameters ranging from 1mm up to 26mm, thus providing solutions for many light-duty or decorative projects as well as heavy industrial applications.

Whilst the smaller diameters (1mm-3mm) work well for picture hanging, clotheslines, and light rigging; the medium sizes (4mm-10mm) are good for deck railing, balustrades, and some marine rigging. Larger diameters (12mm-26mm) handle the more demanding tasks like heavy equipment support, structural cable systems, and commercial applications.

We are able to sell diameters up to 8mm directly online, for the larger diameter ropes simply get in touch for up to date prices.

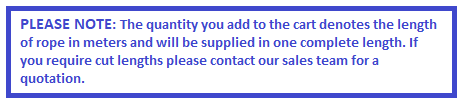

When it comes to the length of rope you require we can supply anything in lengths up to 100 metres which is a full coil.

While 1x19 rope has strength and low stretch qualities, it's less flexible than 7x7, 7x19 or 6x36 constructions. Thus it is not recommended for applications requiring repeated bending or running through pulleys.

Always use quality stainless steel fittings with your rope for best results and to ensure secure connections and maintain the system's integrity.

| Diameter | KG/100M | Kn | >KG |

| 1 | 0.50 | 0.82 | 84 |

| 1.2 | 0.71 | 1.19 | 121 |

| 1.5 | 1.11 | 1.85 | 189 |

| 1.8 | 1.6 | 2.67 | 272 |

| 2 | 1.98 | 3.3 | 336 |

| 2.3 | 2.62 | 4.36 | 444 |

| 2.5 | 3.09 | 5.15 | 525 |

| 3 | 4.46 | 7.42 | 756 |

| 4 | 7.92 | 13.19 | 1,344 |

| 5 | 12.38 | 20.61 | 2,101 |

| 6 | 17.82 | 29.7 | 3,025 |

| 7 | 24.25 | 40.4 | 4,117 |

| 8 | 31.68 | 52.8 | 5,377 |

| 9 | 40.09 | 66.8 | 6,806 |

| 10 | 49.50 | 82.4 | 8,402 |

| 11 | 59.89 | 99.7 | 10,167 |

| 12 | 71.28 | 118.7 | 12,099 |

| 14 | 97.02 | 161.6 | 16,468 |

| 16 | 126.72 | 211 | 21,509 |

| 19 | 178.69 | 298 | 30,332 |

| 22 | 239.58 | 399 | 40,666 |

| 26 | 334.62 | 557 | 56,798 |

| Minimum Breaking Force Factor | |||

| K= 0.525 | |||

| Nominal Length Mass Factor | |||

| W=0.495 | |||